Creation of the first SIM card made from recycled plastic

Thales and Veolia have joined forces to create the first eco-designed SIM card made from recycled plastic. The polymer, a plastic found in high concentrations in household

In line with Thales’ strategy for a low-carbon future, the priority is to reduce, or even completely phase out, the use of fossil energy on our sites, in two ways:

- through the insulation of the buildings, since fossil energy (gas) is mainly used for heating purposes on our sites,

- by recovering the waste heat produced by industrial equipment and using it to heat our sites.

Refrigerant fluids in the cooler units used to maintain a low temperature in the data center constitute another source of carbon emissions.

Therefore, the project had three objectives:

(i) to recover the heat produced by the data center,

(ii) to replace the refrigerant fluids used in the cooler units by a gas that has a smaller carbon footprint and

(iii) install comfort cooler units whose electricity consumption adjusts according to the required cooling capacity.

Replacement of old cooler units used on the site and in the data center by modern cooler units with heat recovery and more environmentally friendly gases, as well as injecting the hot water generated into the site’s heating system.

As regards the comfort cooler units, the replacement of the units goes hand in hand with automated functions (linked to the BACS directive) enabling them to be operated according to the external temperature. Gas continues to be used in the event of intense cold conditions.

on which the project has a significant impact

Scope 1 – Reduce the use of gas for heating purposes on site. Reduce emissions due to leaked refrigerant fluids from cooler units

Quantification:

Scope 2 – Increase the consumption of electricity via cooler units in order to recover the heat, compensated by ceasing to use gas for heating purposes.

Quantification:

Calculation carried out as part of a contract relating to energy performance.

€1.8 M financed 100% by the Energy Saving Certificates

The project was launched in March 2020, and finalised in December 2020

The project is located on the Thales AVS France SAS site in Toulouse, on which there is a data center used by several Thales entities.

Following this project, another project is underway on the Elancourt site, where data centers are in place, and this will enable savings of 1500 tCO2e per year.

Partnership with Vinci to carry out the project.

alice.pruvot@thalesgroup.com

Thales and Veolia have joined forces to create the first eco-designed SIM card made from recycled plastic. The polymer, a plastic found in high concentrations in household

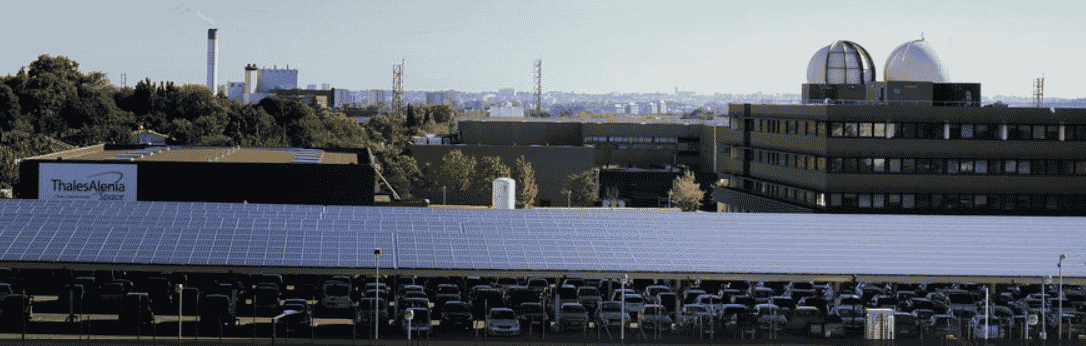

The Thales Group has installed photovoltaic solar canopies over the car park at its Toulouse site to limit the consumption of electricity…

The PureFlyt Flight Management System solution to be deployed by Thales will make it possible to optimise an aircraft’s flight path to reduce…

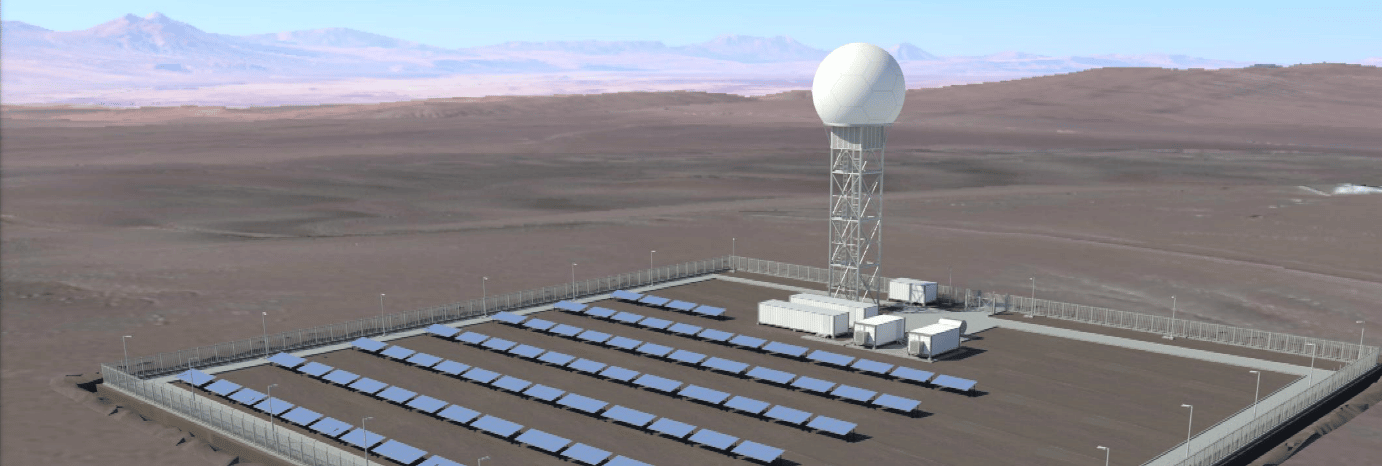

Thales is to deploy the world’s first entirely solar-powered Air Traffic Control radar station in Calama, Chile…