PureFlyt: A flight management system that optimises aircraft CO2 emissions

The PureFlyt Flight Management System solution to be deployed by Thales will make it possible to optimise an aircraft’s flight path to reduce…

Promote the use of recycled plastics in the design of SIM cards and thereby reduce the carbon footprint of their manufacture.

Thales and Veolia have joined forces to create the first eco-designed SIM card made from recycled plastic (polystyrene) from old refrigerators, thereby helping to reduce the environmental impact of a market of more than four and a half billion SIM cards (global production in 2020, of which Thales is the leader with a 25% market share).

The use of recycled material in an industrial manufacturing process allows Thales to replace the production of nearly 5,000 tons of virgin plastic (ABS) per year, corresponding to a reduction of 16 times less CO2eq emissions per SIM card produced (SRP ref – eco profile of recycled/ virgin PS (Polystyrene)).

The eco-SIM card supports the ambitious sustainable development objectives of Thales and its mobile operator customers.

The project has also enabled Veolia to demonstrate that recycled plastic can meet the same technical specifications as virgin plastic, while still retaining its competitive advantages

on which the project has a significant impact

Scope 1 – replacement of virgin resin with recycled resin

Emissions avoided – replacement of virgin resin with recycled resin

Tpolystyrene x 0,138

5000 t x 0.138 = 690 t CO2 EqNB 1: Emission factors include waste collection, transport, sorting and preparation (washing, grinding, densification, micronisation, granulation, compounding)

NB 2: Thales also offsets residual emissions via a CarbonNeutral® certified programme with The Carbon Neutral Protocol, this impact is not included in the calculations.

Not communicated

2019

The manufacturing of the SIM cards takes place at several Thales sites around the world (in Europe, Asia and Central America) and the plastic, which is derived from household electrical waste (particularly end-of-life refrigerators), comes from Veolia's sorting and dismantling unit in Angers (49) and is processed in France at the Froissy recycling plant (60).

The use of recycled plastic brings other environmental benefits compared to virgin plastic resin: less pollution of water, air, living ecosystems, and also less consumption of non-renewable energy for its production (12 times less for polystyrene – see SRP ecoprofile)

This project is applicable to the entire world market for SIM cards (4 times the production of Thales).

A study within Thales is underway to use recycled plastic for other technological products (e.g. banking terminals).

The operation is conducted in partnership between Thales et Veolia.

For Veolia : jean-christophe.delalande@veolia.com For Thales : yannick.burianne@thalesgroup.com

The PureFlyt Flight Management System solution to be deployed by Thales will make it possible to optimise an aircraft’s flight path to reduce…

Thales has installed a heat recovery system within its data center on its Toulouse site in order to reduce its carbon footprint by replacing gas heating with a system …

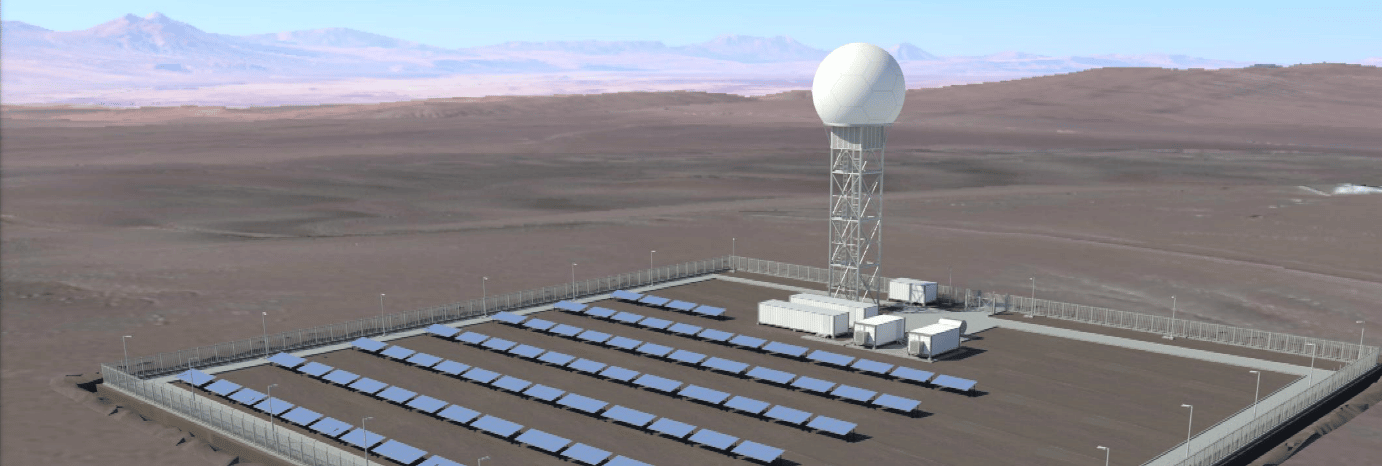

Thales is to deploy the world’s first entirely solar-powered Air Traffic Control radar station in Calama, Chile…

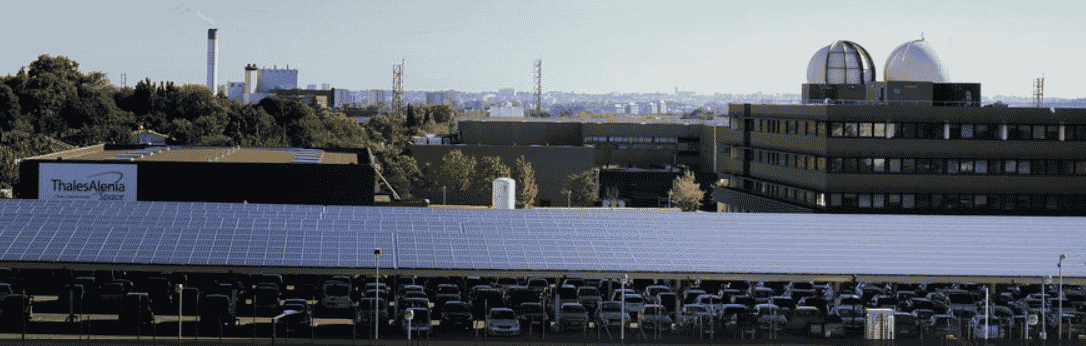

The Thales Group has installed photovoltaic solar canopies over the car park at its Toulouse site to limit the consumption of electricity…

AFEP (Association of French large companies) is an association representing 111 of the largest companies operating in France. It participates in the public debate with the ambition to provide pragmatic answers in favour of the development of a competitive and sustainable French and European economy, conducive to the growth of all companies.