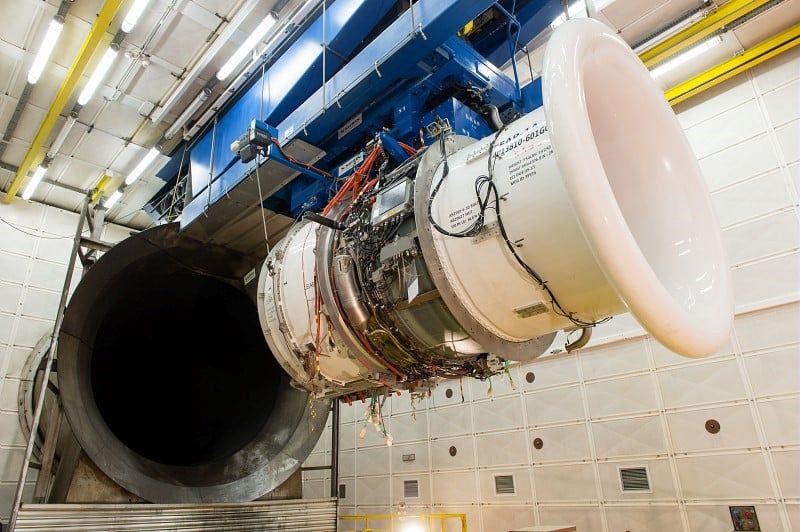

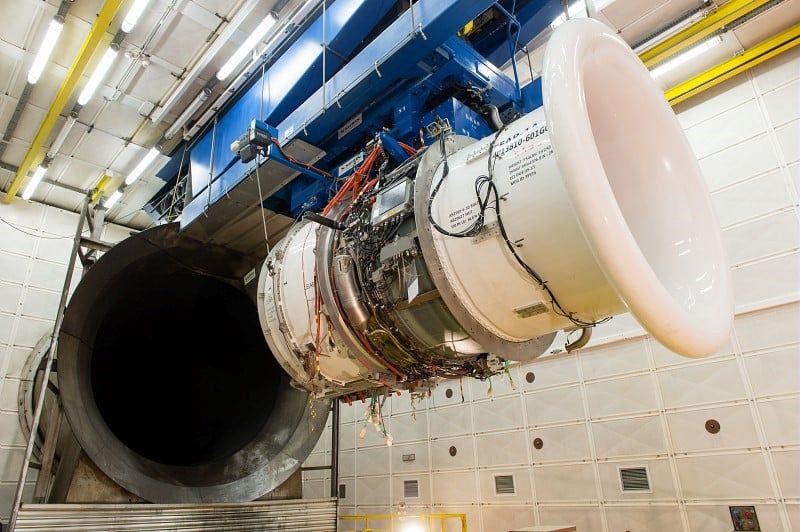

Use of advanced biofuels for engine tests

In order to reduce its greenhouse gas emissions and support the emerging sustainable aviation fuel sector, Safran decided to incorporate advanced biofuels into the kerosene used on aircraft and

To decarbonize the energy used on the Milmort site through the implementation of cogeneration systems, solar panels and an industrial wind turbine.

The on-site production of renewable energy, including self-consumption, is the best way to decarbonize the energy required to operate the site (industrial processes or infrastructure).

on which the project has a significant impact

Scope 1 – Burning of biogas in the cogeneration plants

Scope 2 – Cogeneration: coproduction of electricity:

Scope 2 – Solar panels:

Scope 2 – Wind turbine:

Scope 3 – Production of biogas

Scope 3 – Solar panels:

Scope 3 – Wind turbine:

Avoided Emissions – Biogas: emissions avoided by the farmer :

Before the project, the Milmort site used 48,371 MWh of energy per year:

– 21,376 MWh of fossil energy (Natural gas; EF = 0.227 tCO2/MWh LCV) per year for the heating of the buildings and the heat requirements of the industrial processes

– 26,995 MWh of electricity taken from the Belgian network (EF = 0.277 tCO2/MWh) Namely, CO2 emissions of 12,330 tCO2/year

The project covers these energy needs (considered to be equal to the pre-project situation)

– 10,400 MWh of biogas (EF = 0.024 tCO2/MWh LCV) per year for heating and the heat requirements of the industrial processes

– 7,200 MWh of electricity generated from cogeneration (EF = 0 tCO2/MWh, in the case of cogeneration, the EF is applied to heat)

– 1,080 MWh of electricity generated from solar panels (EF = 0.045 tCO2/MWh)

– 2,000 MWh of electricity generated from the wind turbine (EF = 0.010 tCO2/MWh)

This results in an improvement in CO2 emissions of around 4,890 tCO2/year

1400 k€

2018

Milmort, Belgium

This project fully meets SDG 7 Affordable and clean energy. It also contributes to SDG 9 Industry, Innovation and Infrastructure, as it enables the site’s modernization (greater energy independence, modernization of infrastructure)

All of these projects can be reproduced, subject to compliance with the legislation and any incentives in place.

These projects also desensitize a site to market prices thanks to energy that is less expensive than that sold on the market. In the least favorable scenario, the energy price is identical to that of the market. This is the case, for example, for biogas, for which regional assistance measures offset the additional cost when the biogas is used in a cogeneration plant. However, the decarbonization is significant.

To reproduce this project successfully, the assistance of experienced suppliers is necessary. These suppliers must also be familiar with existing legislation and incentives, which are often complex. It is therefore important to rely on local players for each area.

As all of these forms of technology are very mature, these projects are carried out within a client-supplier framework.

eric.englebert@safrangroup.com

In order to reduce its greenhouse gas emissions and support the emerging sustainable aviation fuel sector, Safran decided to incorporate advanced biofuels into the kerosene used on aircraft and

Safran Electronics & Defense implemented on its Montluçon site a Green Days initiative that was broken down into several actions that aimed to save energy and improve energy efficiency..