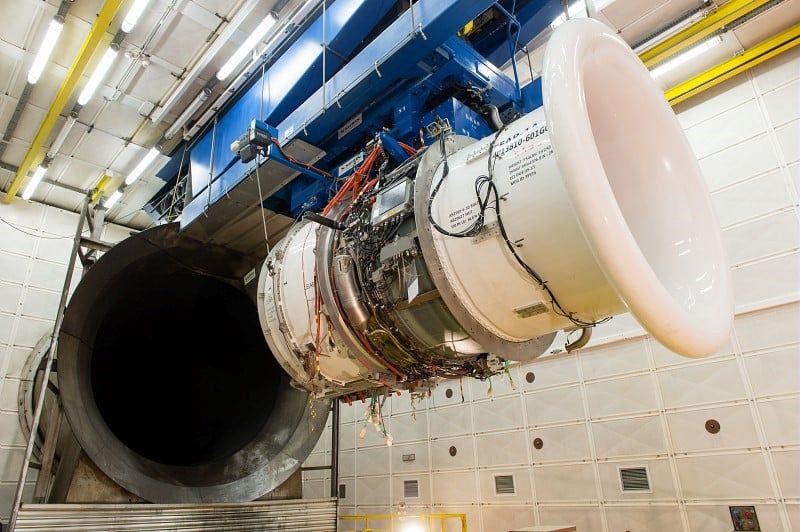

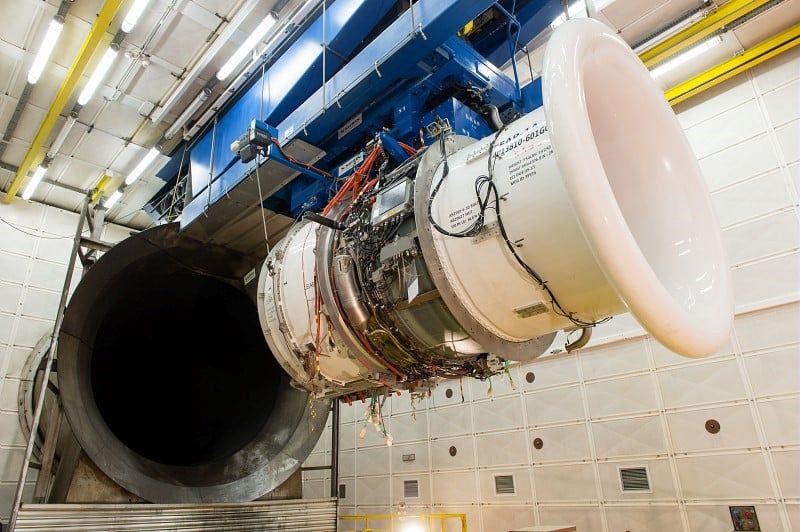

Use of advanced biofuels for engine tests

In order to reduce its greenhouse gas emissions and support the emerging sustainable aviation fuel sector, Safran decided to incorporate advanced biofuels into the kerosene used on aircraft and

Aim of the Green Days initiative: to save energy and reduce the GHG emissions of the Montluçon site thanks to investments made on the site and the roll-out of best practice (eco habits)

This initiative responds to the following sub-goals:

The Green Days initiative on the Montluçon site was broken down into various actions which were taken:

on which the project has a significant impact

Scope 1 – Evolution of the natural gas bill correlated with the evolution of climate severity (EF: 0.169 kgCO2 / kWh)

Scope 2 – Evolution of the electricity bill correlated with the evolution of activity (EF: 0.04 kgCO2 / kWh)

Scope 3 – Evolution of the electricity bill correlated with the evolution of activity and evolution of the natural gas bill correlated with the evolution of climate severity (EF elec: 0.018 kgCO2 / kWh – EF gas: 0.0357 kgCO2 / kWh)

50% improvement in the site’s energy performance between 2012 and 2019.

Cumulative gain of 2.6 million euros

3.8 M€

2012

Montluçon, Allier

This Green Days initiative offers several benefits to the project owner:

The methods of all of these projects can be reproduced: size to exact needs, implement the best methods available, use the energy sources available. These projects also desensitize a site to market prices.

Several factors play a role in the initiative’s success:

As all of these forms of technology are very mature, these projects are carried out as part of works launched through calls for tenders. The projects are carried out with local small and medium enterprises and/or large national groups.

Awareness-raising actions are performed in-house with the support of Ademe through local “Energy info” appointments.

amandine.maugarnis@safrangroup.com

In order to reduce its greenhouse gas emissions and support the emerging sustainable aviation fuel sector, Safran decided to incorporate advanced biofuels into the kerosene used on aircraft and

In order to decarbonize some of the energy used on its Milmort site, Safran implemented three types of renewable-energy installation: solar panels, a wind turbine and cogeneration plants fueled by locally…