Non Melting energy project

In 2018, Verallia initiated a process to identify and activate levers for reducing the energy consumption of the industrial processes implemented at its sites (excluding melting). Identify and activate levers for reducing…

The main objective of this project is to reduce CO2 emissions from the electricity consumption of the Mondego production site.

Self-consumption of solar energy produced on site by installing photovoltaic panels on the available surface of the site (> 31,000 m2) on the roof and on the ground: 5.6 MW installed.

on which the project has a significant impact

Scope 1 –Self-consumption of electricity corresponding to 14% of the consumption of the site

The installation of the solar panels allows to produce 14% of the total consumption of the Mondego site (in Figueira da Foz, Portugal). The average emission factor of the electricity consumed by the site is reduced by 14% considering that the emission factor of the electricity produced by the solar panels is 0 kgCO2/MWh. The CO2 emission saving represents 3115 tCO2. In 2020, the electricity consumption of the Mondego site (in Figueira da Foz, Portugal) is of the order of 57 MWh. The installation of the solar panels will produce 8.3 MWh. Considering that the emission factor of the Portuguese grid is specify

Capex = 0 for Verallia

Q1 2022

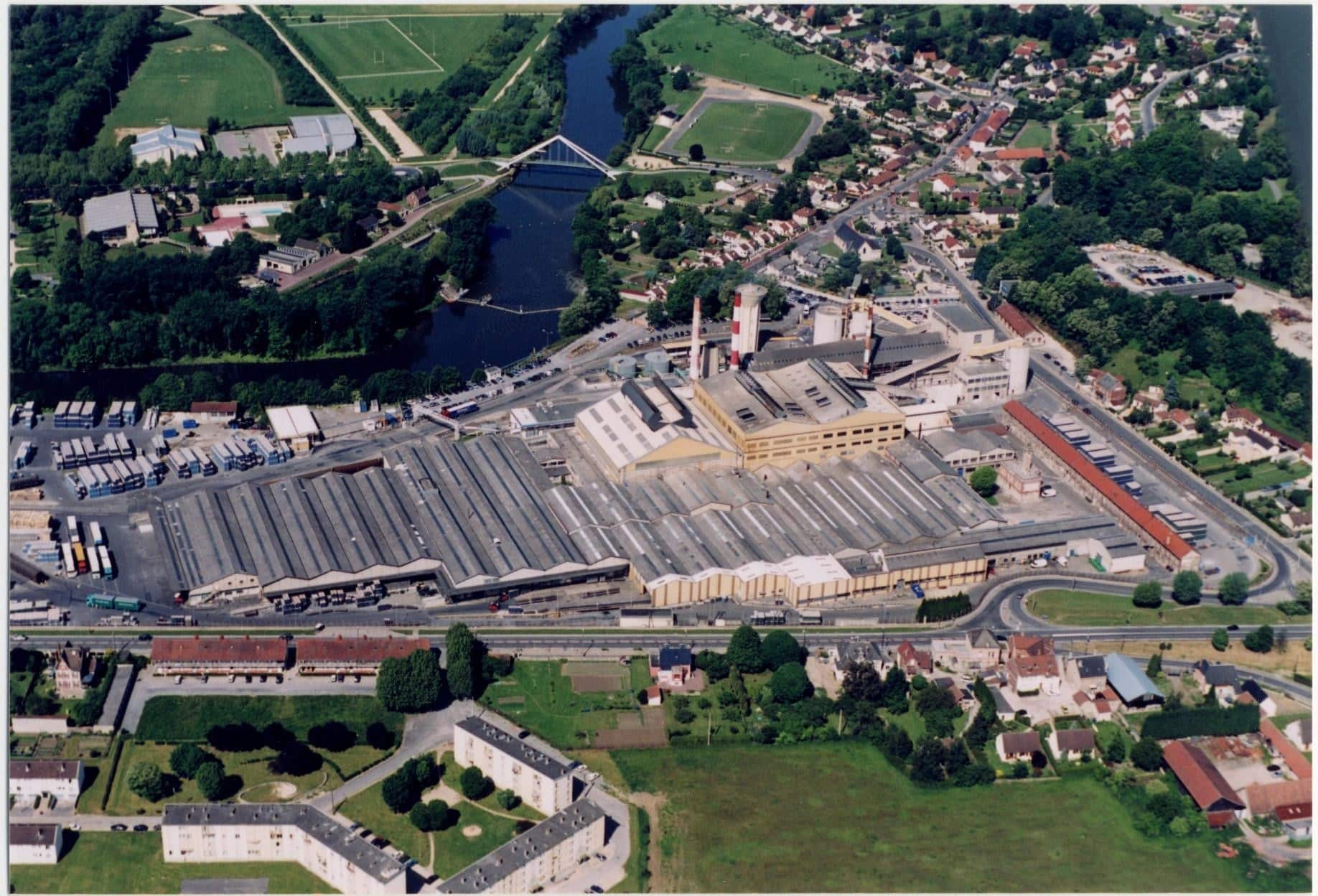

Mondego, Portugal

The project contributes to SDG 9 Industry, Innovation, Infrastructure and SDG 12 Responsible Consumption and Production, by increasing the use of renewable energy.

This on-site photovoltaic panel project is the first one carried out by Verallia.

The goal is now to duplicate it on the various Verallia sites when conditions permit.

This initiative is fully in line with Verallia’s objective of achieving at least 60% of renewable and low-carbon energy in its supplies by 2025.

A local partnership has been initiated through this project.

corporate.communication@verallia.com

In 2018, Verallia initiated a process to identify and activate levers for reducing the energy consumption of the industrial processes implemented at its sites (excluding melting). Identify and activate levers for reducing…

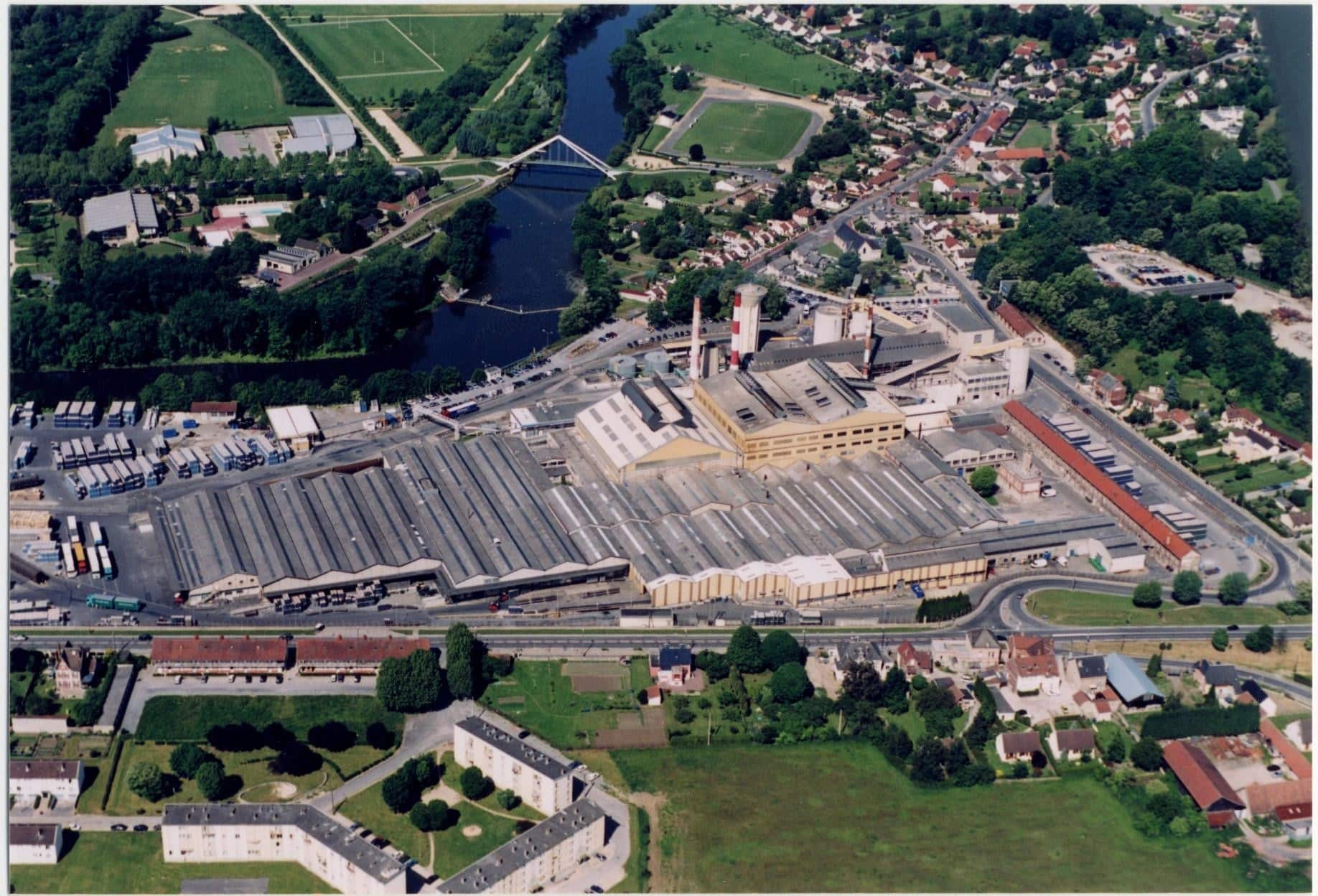

Verallia is developing a de-mixing capacity for white cullet at the Everglass Rozet Saint Albin site, which will increase cullet rates in the white glass furnaces. This project will reduce energy consumption (natural gas) of the white glass furnaces …